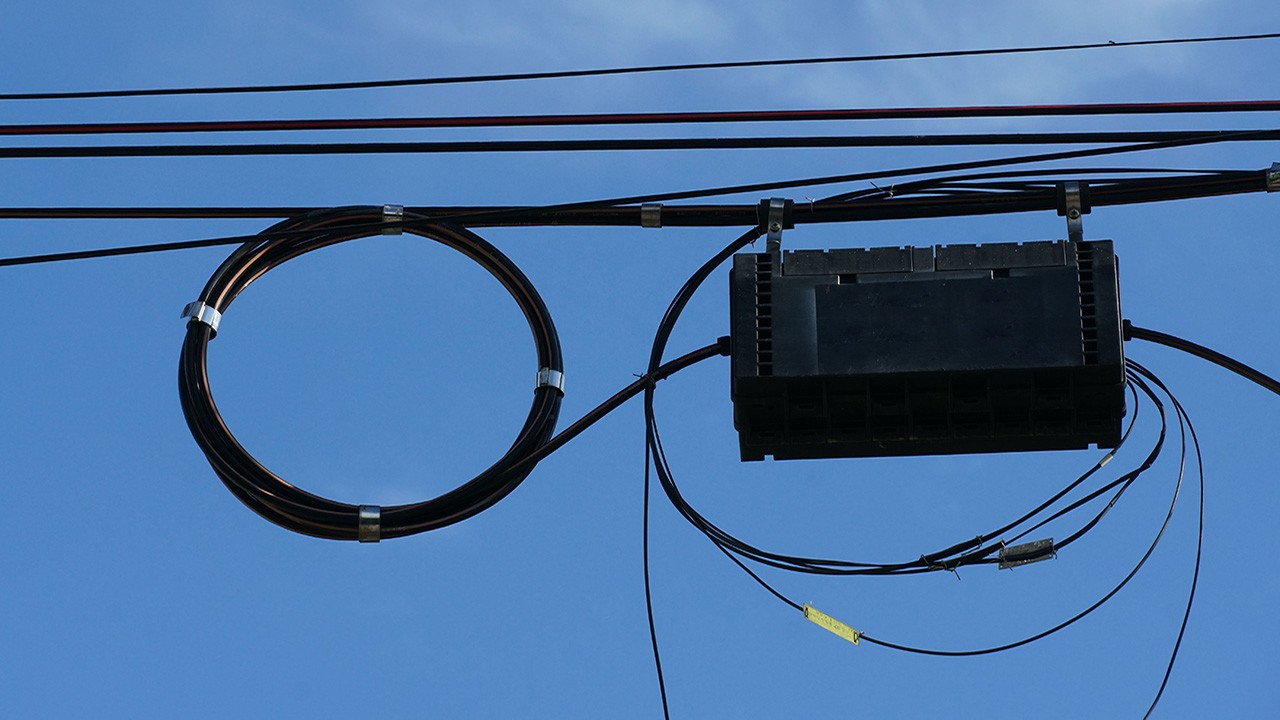

Big equipment gets all the attention but it’s the little things that cause the most headaches. In fiber broadband deployments, poor cable management can introduce long-term operational risks, increase maintenance costs, and degrade network performance. Whether you’re wiring a brand-new subdivision (greenfield) or retrofitting an older neighborhood (brownfield), cable management in the outside plant (OSP) helps ensure stronger network performance with fewer maintenance headaches.

Why Cable Management Matters

Cable management isn’t just about keeping things tidy. It’s about keeping your network functional, future-ready and frustration-free. Done right, it improves:

- Network Reliability – Prevents fiber bends, crush points, or tension that can degrade signal performance.

- Serviceability – Allows field teams to quickly identify, troubleshoot, and perform upgrades with minimal disruption.

- Safety – Minimizes trip hazards and prevents damage to exposed cables.

- Aesthetic Compliance – Meets municipal and homeowner aesthetic expectations, especially in visible areas.

When you cut corners on cable organization, the costs add up. Micro bending, signal loss, unnecessary truck rolls, and even a rework – make for unhappy customers.

Key Challenges: Greenfield vs. Brownfield Deployments

Greenfield Deployments: Don’t Mistake a Blank Slate for Simplicity

Starting from scratch may sound easier but these mistakes can happen fast:

- Over-Optimistic Duct Loading – Assuming future growth without allowing slack or expansion pathways.

- Skipping Access Points – Saving money now can cost you later in troubleshooting.

- Improper Slack Storage – Leaving excess fiber slack exposed or unmanaged in pedestals or handholes can lead to performance issues.

Brownfield Deployments: Retrofits Aren’t Just Plug-and-Play

With brownfield deployments, you’re facing a number of legacy constraints:

- Space Limitations – Existing ducts, conduits, or structures may already be congested or inaccessible.

- Legacy Cabling Coexistence – Risk of damaging legacy copper or coax during fiber overlays.

- Aesthetic Restrictions – Visible cables often get flagged by neighborhoods or municipalities.

- Unmapped Infrastructure – Lack of accurate records can result in accidental cuts or forced rerouting.

Best Practices for Smarter Cable Management

So, how should you approach cable management for your next project? These five practices lay the groundwork:

1. Plan Slack Storage with Purpose

- Use purpose-built slack storage solutions such as slack storage baskets, trays, or pre-engineered pedestals designed with slack management in mind

- Avoid leaving coils or loops of cable loose in handholes or pedestals

2. Respect Minimum Bend Radius and Pulling Tensions

- Train installers on minimum bend radius and on the specific handling requirements of fiber optic cables

- Use fiber management hardware that enforces bend radius protection

3. Label and Document Every Segment

- Use durable weather-resistant labels to clearly label cables, closures, and ports to enable future identification

- Keep records updated as-built, not as-planned

4. Use Modular and Scalable Access Points

- Plan for future expansion by using closures and pedestals that support additional ports and slack without full replacement

5. Inspect and Verify Work Before Closure

- Before finalizing the installation at pedestals, closures or handholes, inspect cable placement to ensure it meets bend radius, labeling, and slack storage guidelines

Don’t Treat Cable Management Like an Afterthought

Poor cable management today is tomorrow’s service call or even worse, a total rework. Whether you’re building a new network or upgrading an existing one, ensuring your installers follow proven cable management best practices will protect your investment, reduce long-term costs, and deliver better customer experiences. If you are planning a project, make sure your specifications, RFQs, and field inspections include cable management expectations. Your network – and your future customers – depend on it.

The same disciplined approach to cable routing and management that Panduit has emphasized in high-performance data centers is now being thoughtfully extended to outside plant environments – where fiber damage is harder to detect but just as critical to prevent. Applying this level of control from the outset helps build networks that are not only highly performing, but also resilient and easier to maintain.

Learn more about Panduit Broadband solutions: www.panduit.com/ftth